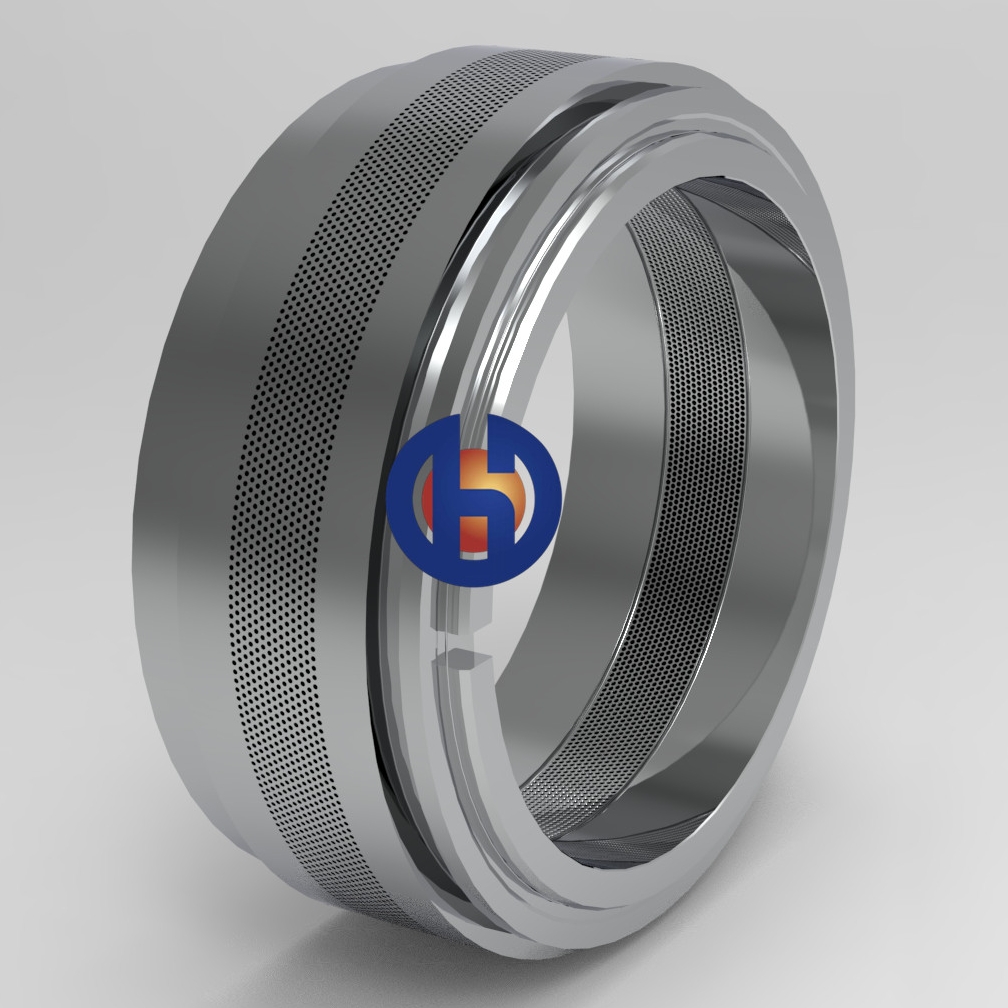

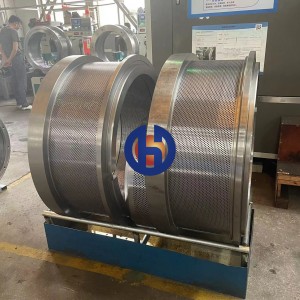

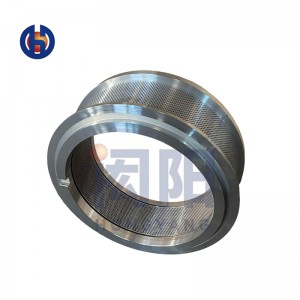

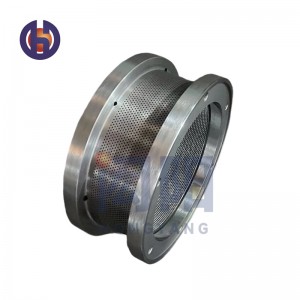

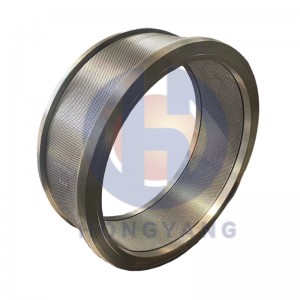

I-CPM Series Ring Die For Pellet Mill

I-Ring Die Materials kanye Nokwelashwa Kokushisa

I-ring die ngokuvamile yenziwe nge-carbon structural steel, i-structural alloy steel, nensimbi engagqwali ngokusebenzisa ukubumba, ukusika, ukubhoboza, ukwelashwa kokushisa, nezinye izinqubo. Izinto ezisetshenziswa eringini ziyafa kanye nenqubo ngayinye yokucubungula inomthelela oqondile empilweni yayo yesevisi, ikhwalithi yegranulation kanye nokuphumayo. Insimbi yesakhiwo sekhabhoni ngokuyinhloko iqukethe insimbi engama-45, ubulukhuni bayo bokwelapha ukushisa ngokuvamile obungu-HRC45~50, futhi ukumelana kwayo nokuguga nokugqwala kubuthaka, okuye kwaqedwa; Insimbi ye-alloy ngokuyinhloko iqukethe i-20CrMnTi impahla, engaphansi kokwelashwa kokushisa okungaphezulu okufana nokugqumisa phezulu. Ukuqina kokwelashwa kungaphezulu kwe-HRC50 futhi kunezakhiwo ezinhle zokuhlanganisa. Isikhunta sendandatho esenziwe ngale nto sinamandla amakhulu futhi singcono ukumelana nokugqoka kunensimbi engu-45, kodwa ukonakala kwayo ukumelana nokugqwala okungekuhle. Nakuba izindleko zesikhunta esisodwa sendandatho ziphansi ngokuqhathaniswa, izindleko zokukhiqiza amathani wezinto ezibonakalayo ziphakeme kunalezo zesikhunta sensimbi engagqwali lapho sisetshenziswa, futhi manje sesiphelile; Izinto zensimbi engagqwali ngokuyinhloko ziyi-4Cr13. Ukuqina nokuqina kwalezi zinto zokwenziwa kuhle. Ukwelashwa kokushisa kuwukudubula sekukonke, ubulukhuni bukhulu kune-HRC50 futhi inokumelana nokuguga okuhle nokumelana nokugqwala. Impilo yesevisi yinde, futhi izindleko ze-ton ring mold ziphansi.

Ukwakhiwa kwe-4Cr13 Material Ring Die

Ngendandatho efa yento engu-4Cr13, umthombo wayo wekhwalithi kufanele uqale ku-ingot: ukwakheka kwamakhemikhali (ingxenye enkulu%) yensimbi yensimbi engu-4Cr13 yile: C okuqukethwe ≤ 0.36 ~ 0.45, okuqukethwe kwe-Cr 12 ~ 14, Okuqukethwe kwe-≤ 0.80⤉ okuqukethwe ≤ 0.80, S 0.03, okuqukethwe kwe-P ≤ 0.035; Ekusetshenzisweni kwangempela, impilo yesevisi yendandatho ifa cishe ngo-12% wokuqukethwe kwe-Cr ingaphezu kwe-1/3 emfushane kunaleyo ye-ring die ene-14% yokuqukethwe kwe-Cr ngaphansi kwezimo ezifanayo zezinye izindlela zokwelapha; Ngakho umthombo wekhwalithi ye-ring die uvela echibini lensimbi. Akudingekile kuphela ukuqinisekisa ukuthi okuqukethwe kwe-Cr kungaphezu kuka-13%, kodwa futhi nokuqinisekisa ukuthi usayizi nokuma kuhlangabezana nezidingo zokubunjwa.

Uchungechunge lwe-CPM

| I-S/N | INDLELA | UsayiziOD*ID*ububanzi bonke*ububanzi bephedi -mm |

| 1 | I-CPM MASTER | 304*370*90*60 |

| 2 | I-CPM 21 | 406*558*152*84 |

| 3 | CPM16/25 | 406*558*182*116 |

| 4 | I-CPM A25/212 | 406*559*212*116 |

| 5 | I-CPM2016-4 | 406*559*189*116 |

| 6 | I-CPM3000N/CPM3020-4 | 508*659*199*115 |

| 7 | I-CPM3016-4 | 559*406*190*116 |

| 8 | I-CPM3016-5 | 559*406*212*138 |

| 9 | I-CPM3020-6/CPM3000W | 660*508*238*156 |

| 10 | I-CPM3020-7 | 660*508*264*181 |

| 11 | CPM3022-6/CPM7000/CPM7122-6/CPM7722-6 | 775*572*270*155 |

| 12 | I-CPM3022-8 | 775*572*324.5*208 |

| 13 | I-CPM7726-6 | 890*673*325*180 |

| 14 | I-CPM7726-8 | 890*673*388*238 |

| 15 | I-CPM7726-9SW | 890*672*382*239 |

| 16 | I-CPM7932-9 | 1022.5*826.5*398*240 |

| 17 | I-CPM7932-11 | 1027*825*455.5*275 |

| 18 | I-CPM7932-12 | 1026.5*828.5*508*310.2 |

| 19 | I-CPM7730-7 | 965*762*340*181 |

I-CPM 2016-4 CPM 3020-4 CPM 3020-6 CPM 3022-6 CPM 3022-8 CPM 7722-2 CPM 7722-4 CPM 7722-6 CPM 7722-7 CPM 7726-7 CPM 7726-7 CPM4 C7630 I-CPM 7730-8 CPM 7930-4 CPM 7930-6 CPM 7930-8 CPM 7932-5 CPM 7932-7 CPM 7932-9 CPM 7932-11 CPM 7932-12 CPM 9636-37 C2912-29