Isikrini se-Hammer Mill Somshini Wokugaya

Izici Zomkhiqizo

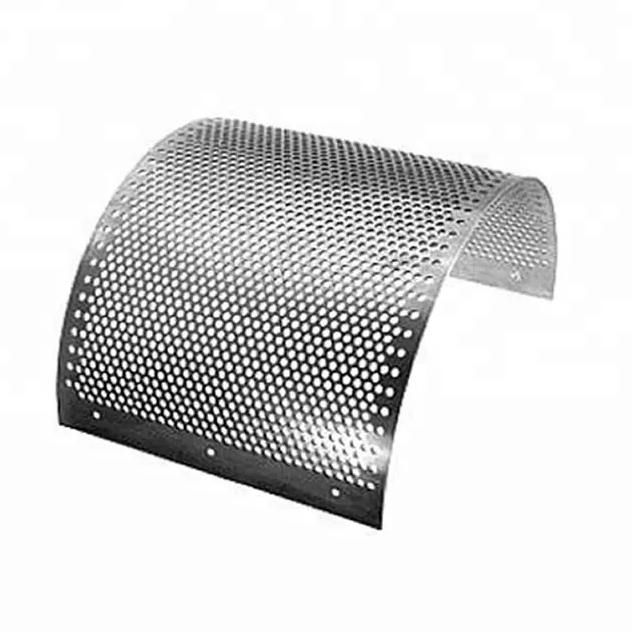

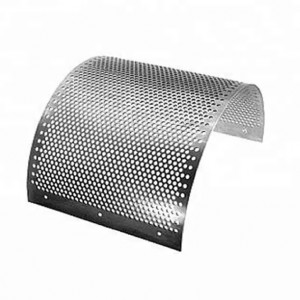

1. I-Hammer Screen ingenye yezingxenye ezibalulekile zomshini wesando, igcina isigayo sesando sisebenza kahle, kodwa futhi siyingxenye egqokekayo.

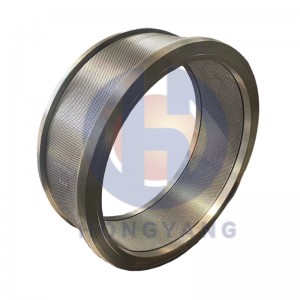

2. Ishidi lesikrini lisetshenziswa emshinini wesando ngesakhiwo esilula nokukhiqiza okulula, isikrini esiyicylindrical sisetshenziswa kakhulu embonini.

3. Inethonya elibalulekile kumshini wokugaya. Indawo nekhwalithi yesikrini inomthelela oqondile ekusebenzeni kahle kokuhlola kanye nempilo yokusebenza kwesikrini.

4. Usayizi wembobo uhambisana nosayizi we-pellet. Ingacutshungulwa ibe yizimbobo ezihlukahlukene, ezifana no-0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, no-4.0mm.

Uhlobo Lwezikrini

Singahlinzeka ngezikrini zokugaya isando ezinosayizi abahlukahlukene. Uma kwenzeka noma iyiphi yalezi zinto ibe nentshisekelo kuwe, sicela usazise. Sizokujabulela ukukunikeza isaphulelo ngemuva kokuthola imininingwane yakho eningiliziwe. Sinonjiniyela bethu be-R&D abangochwepheshe ukuze bahlangabezane nanoma yiziphi izidingo.

| Ubukhulu(mm) | Ububanzi Bembobo(mm) | I-Hole Area Ratio | Ukubekezelela Ububanzi Bomgodi | Ukubekezelela Ububanzi Bendawo Yezimbobo |

| 1.0 | 1.0 | 20% | ±0.05 | ±0.12 |

| 1.2 | 30% | ±0.05 | ±0.15 | |

| 1.2 | 1.2 | 30% | ±0.05 | ±0.15 |

| 1.5 | 33% | ±0.05 | ±0.15 | |

| 1.5 | 1.5 | 35% | ±0.06 | ±0.15 |

| 2.0 | 38% | ±0.06 | ±0.15 | |

| 1.8 | 1.8 | 40% | ±0.06 | ±0.15 |

| 2.5 | 48% | ±0.06 | ±0.15 | |

| 2.0 | 2.0 | 42% | ±0.06 | ±0.15 |

| 2.2 | 45% | ±0.07 | ±0.17 | |

| 2.5 | 48% | ±0.07 | ±0.17 | |

| 3.0 | 52% | ±0.07 | ±0.17 | |

| 3.2 | 55% | ±0.07 | ±0.17 | |

| 3.5 | 58% | ±0.07 | ±0.17 | |

| 4.0 | 60% | ±0.07 | ±0.17 |