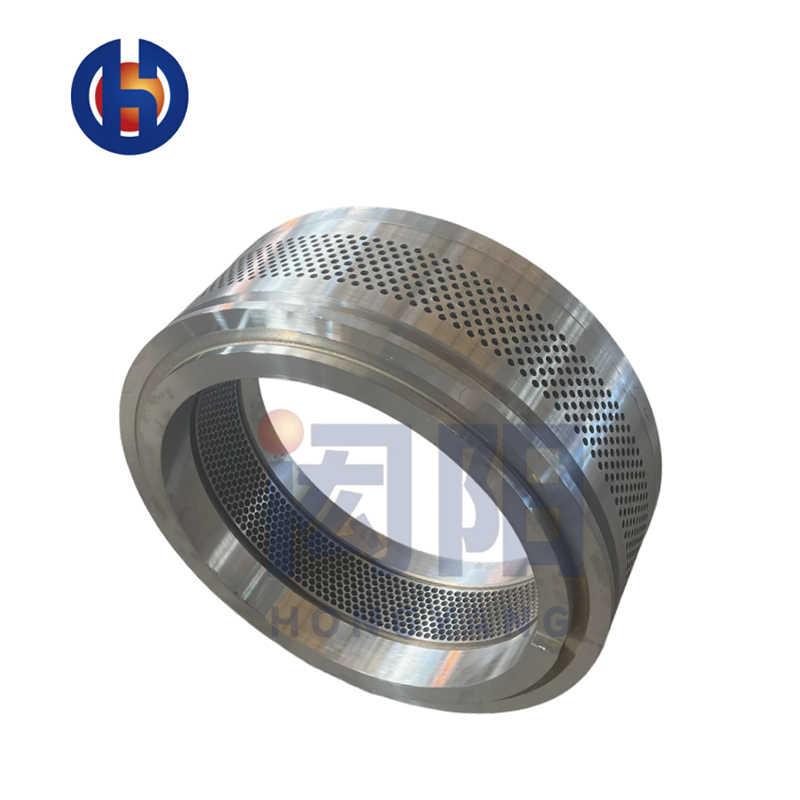

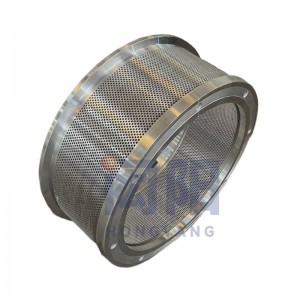

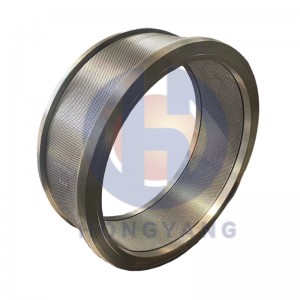

MZLH/ZHENGCHANG Ring Die Pellet Cindezela Die

Ipharamitha Yezobuchwepheshe

Ukucaciswa kobubanzi: Φ6.0mm nangaphezulu

Material: insimbi engagqwali yekhwalithi ephezulu (X46Cr13, 4Cr13), insimbi ye-alloy engagqoki

I-die yamukela inqubo yokwelapha ehlanganisa isithando somlilo kanye nesithando somlilo esiqhubekayo sase-United States, ngokucisha umfaniswano, ukuqedwa okuhle kwendawo kanye nokuqina okuphezulu, okuqinisekisa kabili impilo yesevisi.

Imingcele yokucaciswa kwendandatho ye-biomass pellet mill die:

Indwangu: Insimbi ye-manganese yekhwalithi ephezulu ye-chromium

Indawo yokucubungula: 6.00mm - 16.00mm

Ububanzi bangaphandle bomsebenzi ocutshunguliwe: 500mm-1100mm

Ububanzi bangaphakathi bomsebenzi ocutshunguliwe: 400mm-900mm

Ukuqina kobuso: HRC 58-62

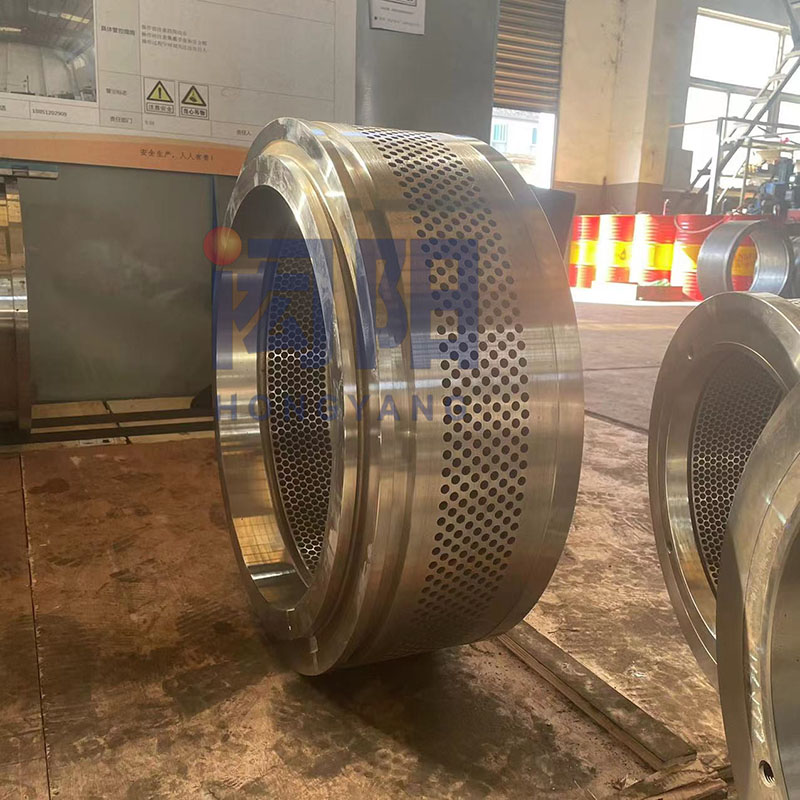

Isibonisi somkhiqizo

Ukugcinwa Komkhiqizo

I-ring die iyingxenye esemqoka yesigayo se-pellet, enesibopho sokubumba impahla eluhlaza ibe ama-pellets. Ukugcina kanye nokuhlinzeka ngokufanele i-ring die kubaluleke kakhulu ukuze kuqinisekiswe ukusebenza kahle kwe-pellet mill kanye nokuqinisekisa ukuthi ama-pellets akhiqizwayo asezingeni elihle. Nawa amanye amathiphu angakusiza ukuthi ulondoloze ukufa kwendandatho yesigayo sakho:

1. Gcina iringi ihlanzekile

Enye yezinto ezibalulekile ongayenza ngeringi yakho ukuyigcina ihlanzekile. Susa noma iyiphi impahla eyakhelwe phezulu noma udoti esikhunjeni futhi uqiniseke ukuthi ayinayo imifantu noma umonakalo. Ungakwazi ukuhlanza isikhunta ngokusebenzisa ibhulashi elithambile ngokusebenzisa izimbobo futhi ukhiphe noma iyiphi insalela eyakhelwe phezulu.

2. Ukugcoba amafutha njalo

Isinyathelo esilandelayo sokulungisa siwukugcoba ngezikhathi ezithile idayi yeringi. Lokhu kuzosiza ekuvimbeleni ukungqubuzana, okungakhubaza ukufa futhi kulimaze i-pelletizer. Sebenzisa okokugcoba kwekhwalithi enhle okuhambisana nempahla yeringi.

3. Lungisa igebe phakathi kwe-ring ring kanye ne-pressure roller

Esinye isici esibalulekile ekugcinweni kweringi ukulungisa igebe phakathi kweringi kanye ne-pressure roller. Ukususwa okufanelekile kuqinisekisa ukuthi isitokwe sokudla sicindezelwa kahle, okuholela kumapellets ekhwalithi ephezulu. Ukuvunyelwa kufanele kulungiswe ngokuya ngohlobo lwezinto ezicutshungulwayo kanye nosayizi wezinhlayiyana oyifunayo.

4. Faka esikhundleni isikhunta uma kunesidingo

Ngokuhamba kwesikhathi, indandatho iyafa ingaguga futhi ikhubazeke, okungaholela eqophelweni eliphansi le-pellet ngisho nokulimala kwesigayo se-pellet ngokwayo. Kubalulekile ukufaka esikhundleni sokufa kweringi uma kunesidingo ukuze ugcine ukusebenza kahle. Faka esikhundleni idayizi ngendandatho eyenzelwe umshini wakho wokugaya ukuze uqinisekise ukuthi ilingana kahle.