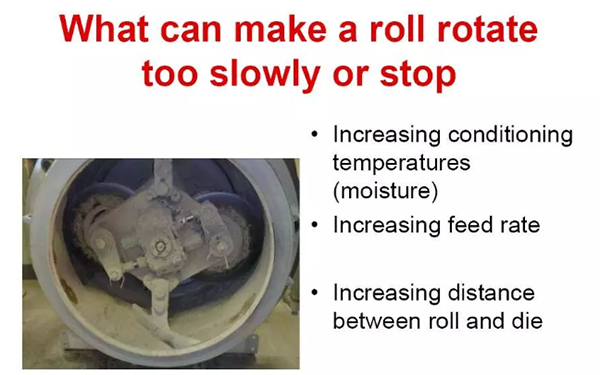

Ukulungiswa kwegebe phakathi kwe-roller yokucindezela kanye nesikhunta esiyindandatho se-granulator yingxenye ebalulekile yokusebenza kwe-granulator. Uma ukulungiswa kwegebe kunengqondo, i-granulator izoba nokuphumayo okuphezulu, ukusetshenziswa kwamandla okuphansi, ikhwalithi yezinhlayiyana ezinhle, ukuguga okuphansi kwe-roller yokucindezela kanye nesikhunta esiyindandatho, nempilo ende yesevisi.

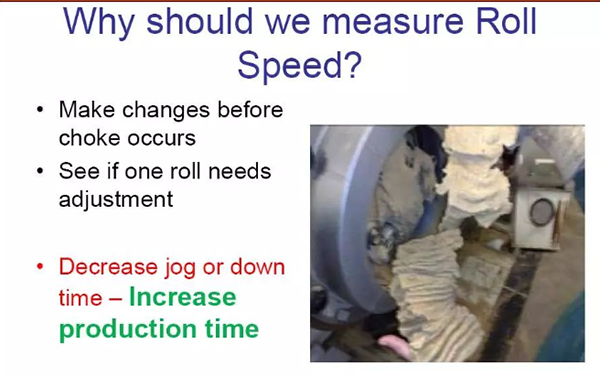

I-granulator ayikwazi ukusebenza kahle, ikhwalithi yezinhlayiyana ayiqinisekisiwe, futhi uma igebe phakathi kwe-roller yokucindezela kanye nesikhunta sendandatho lincane kakhulu, lizogqoka kakhulu, futhi libangele ngisho nokuqhuma kwesikhunta sendandatho. Lokhu kubeka phambili izidingo eziphakeme zama-opharetha we-granulator, okudingeka babe nolwazi olucebile lokulungiswa kwe-pressure roller. Ukuze kuncishiswe umthelela wezinto ezingazinzile ezibangelwa ukusebenza kwabantu, futhi futhi kuncishiswe ukushuba komsebenzi womuntu nokuthuthukisa ukusebenza kahle kokukhiqiza.

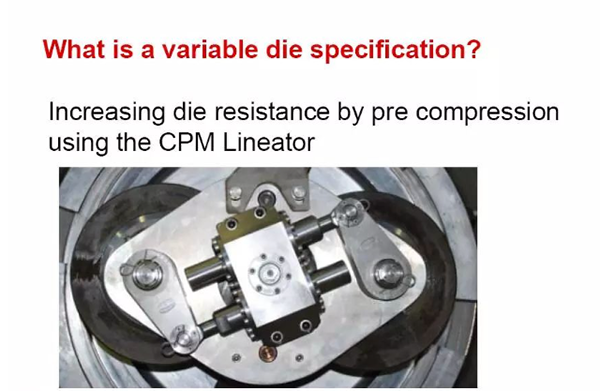

Ubuchwepheshe bokulungisa okuzenzakalelayo kwegebe phakathi kwe-pressure roller kanye nesikhunta esiyindandatho sesivele.

Izimiso zobuchwepheshe:

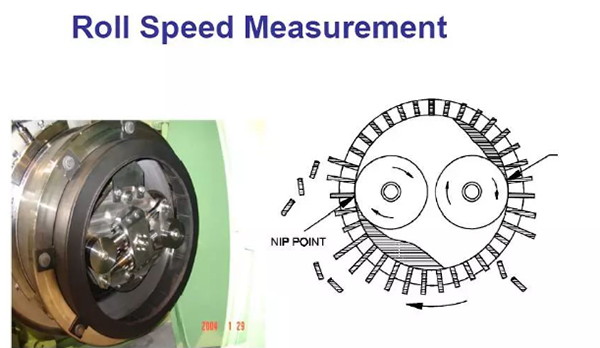

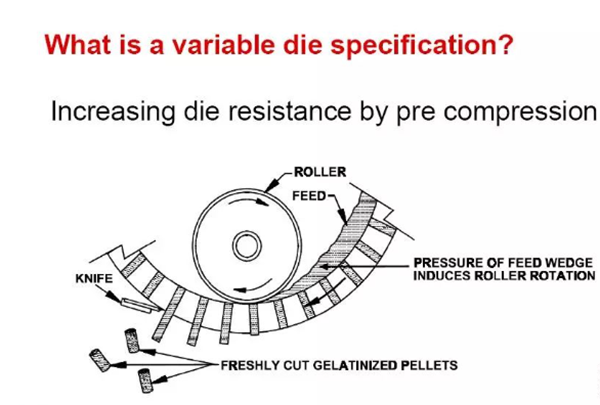

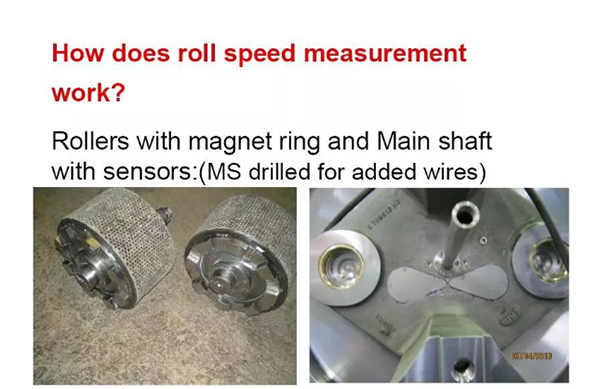

Uhlelo ikakhulukazi lwakhiwe uhlelo lokubulala isilinda samafutha, inzwa ye-engeli, kanye nesistimu yokulawula ye-PLC. Umsebenzi wesistimu yokukhishwa kwe-cylinder kawoyela ukusunduza i-roller yokucindezela ukuze ijikeleze ngokwewashi noma ngokuphambene newashi, ngisho noma igebe phakathi kwe-roller yokucindezela kanye nesikhunta sendandatho sikhuphuka noma sincipha;

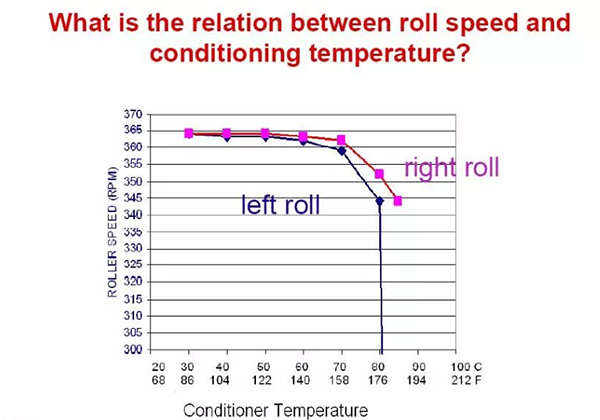

Umsebenzi wenzwa ye-engeli ukuzwa izinguquko ku-angle ye-roller yokucindezela futhi udlulisele isignali yoshintsho ohlelweni lokulawula lwe-PLC; Uhlelo lokulawula lwe-PLC lunesibopho sokuguqula ushintsho ku-engeli ye-roller yokucindezela lube ushintsho kusayizi wegebe phakathi kwe-roller yokucindezela kanye nesikhunta esiyindandatho, futhi siyiqhathanise nenani legebe elimisiwe ukuze kunqunywe isiqondiso nosayizi wesistimu yokukhishwa kwe-cylinder kawoyela kuze kube yilapho igebe langempela kanye negebe elimisiwe lihambisana phakathi kwebanga elivumelekile lephutha.

Izinzuzo zobuchwepheshe:

Isikrini sokuthinta esikusayithi sisebenza njengesixhumi esibonakalayo esisebenzisanayo, okwenza kube lula ukusebenza;

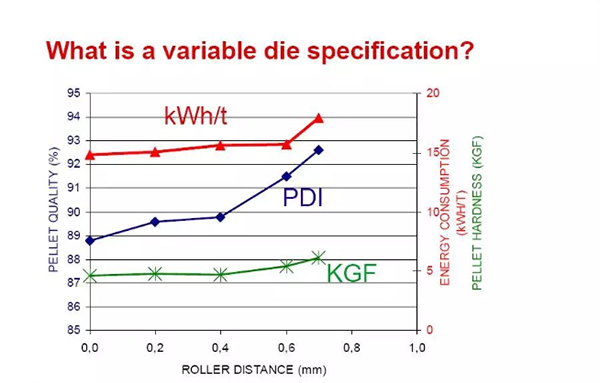

Yehlisa insimbi ekuxhumaneni kwensimbi, unciphise ukuguga ku-roller yokucindezela kanye nesikhunta sendandatho, ukwandisa kakhulu impilo yesevisi;

Yehlisa isidingo sikagesi, yehlise isikhathi sokuphumula, futhi wonge isikhathi nezindleko;

Ukunemba okuphezulu kokulungiswa, iphutha legebe phakathi kwe-roller yokucindezela kanye nesikhunta sendandatho singalawulwa ngaphakathi kwe-± 0.1mm;

Ingalungiswa nganoma yisiphi isikhathi ngesikhathi sokusebenza kwe-granulator, ithuthukise kakhulu ukwethembeka nokusebenza kahle komsebenzi, futhi inciphise umfutho wokusebenza;

Awekho amafutha okugcoba, okwandisa ukuphepha kokuphakelayo.

Isikhathi sokuthumela: Jul-12-2023