Ngesikhathi senqubo ye-granulation yomshini we-pellet yokuphakelayo, kukhona ama-pellets okuphakelayo ngamanye noma ama-pellets okuphakelayo ngamanye anemibala ehlukene, eyaziwa ngokuthi "i-flower feed". Lesi simo sivamile ekukhiqizweni kokuphakela kwamanzi, ikakhulukazi okubonakala njengombala wezinhlayiya ezingazodwana ezikhishwe ekufaneni kweringi ziba mnyama noma zibelula kunezinye izinhlayiya ezivamile, noma umbala ongaphezulu wezinhlayiya ezingazodwana uguquguquka, ngaleyo ndlela uthinte ikhwalithi yokubukeka kwayo yonke inqwaba yokuphakelayo.

Izizathu eziyinhloko zalesi simo yilezi ezilandelayo:

a)Ukwakheka kwezinto ezisetshenziswayo zokuphakelayo kuyinkimbinkimbi kakhulu, kunezinhlobo eziningi kakhulu zezinto ezingavuthiwe, ukuxubana okungalingani, nokuqukethwe komswakama okungahambisani kwempushana ngaphambi kokucubungula izinhlayiya zokuphakela.

b)Umswakama wezinto zokusetshenziswa ezisetshenziselwa imbudumbudu akuhambisani. Enqubweni yokukhiqiza ukudla kwasemanzini, kuvame ukudingekile ukwengeza inani elincane lamanzi ku-mixer ukuze kunxeshezelwe ukulahlekelwa kwamanzi ezintweni zokusetshenziswa ngemuva kokuchotshozwa kwe-ultrafine. Ngemuva kokuxuba, bese ithunyelwa ku-conditioner ukuze ipholile. Abanye abakhiqizi bokuphakelayo basebenzisa inqubo elula kakhulu yokwenza okuphakelayo - faka izinto ezidingekayo zefomula ngqo ku-mixer bese wengeza amanzi anele, esikhundleni sokwenza inqubo enemininingwane enemininingwane nenensayo ngokwezidingo zomsebenzisi. Ngakho-ke, bakuthola kunzima ukuqinisekisa ukusatshalaliswa okulinganiselayo kwezithako zokudla ngokwemibandela yokuncibilika kwamanzi. Uma sisebenzisa lezi zithako ezixubile ekwelapheni isimo, sizothola ukuthi ngenxa yokusebenza kahle kwe-conditioner, okuqukethwe komswakama akukwazi ukuhlakazwa ngokushesha ngokulinganayo. Ngakho-ke, ukuvuthwa kwemikhiqizo yokuphakelayo okucutshunguliwe ngaphansi kwesenzo somusi kuyahluka kakhulu phakathi kwezingxenye ezihlukene, futhi ukulandelana kombala ngemva kwegranulation akucaci ngokwanele.

c)Kukhona izinto ezigaywe kabusha ezine-granulation ephindaphindwayo emgqonyeni we-granulation. Impahla eyimbudumbudu ngemva kwembudumbudu ingashintshwa kuphela ibe umkhiqizo oqediwe ngemva kokupholiswa nokuhlolwa. Impushana ehloliwe ehloliwe noma into encane yezinhlayiyana ivamise ukungena enqubweni yokukhiqiza ukuze kufakwe kabusha imbudumbudu, ngokuvamile kumxube noma ilinde isisele sembudumbudu. Ngenxa yokuthi lolu hlobo lwezinto ezibuyiswayo lufakwe esimweni kabusha futhi luyi-granulated, uma luxubene ngokungalingani nezinye izinto ezisizayo noma luxutshwe nomshini wokubuyisela izinto eziyizinhlayiya ezincane ngemva kokumiswa, ngezinye izikhathi kungase kukhiqize "impahla yembali" kumafomula athile okuphakelayo.

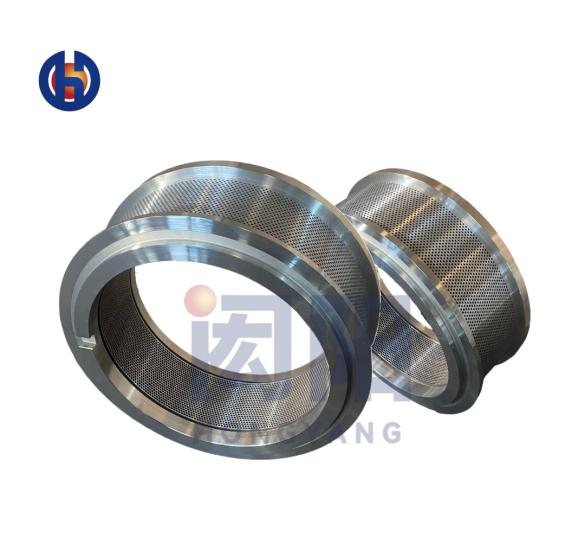

d)Ukushelela kodonga lwangaphakathi lwembobo yokufa eyindandatho akuhambisani. Ngenxa yokungaguquguquki kokuqedwa kwendawo yembobo yokufa, ukumelana nokucindezela kwe-extrusion into ehlangabezana nakho ngesikhathi sokukhipha kuhlukile, okuholela ekushintsheni kombala okungahambisani. Ngaphezu kwalokho, enye i-ring dies inama-burrs ezindongeni zembobo encane, ekwazi ukunwaya ingaphezulu lezinhlayiya ngesikhathi sokukhishwa, okuholela emibaleni ehlukene yendawo yezinhlayiya ngazinye.

Izindlela zokuthuthukisa zezizathu ezine zokukhiqiza "izinto zezimbali" ezibalwe ngenhla sezivele zicacile, ikakhulukazi zilawula ukufana kokuxuba kwengxenye ngayinye kufomula kanye nokufana kokuxuba kwamanzi angeziwe; Ukuthuthukisa ukusebenza kokucisha nokushisa kunganciphisa izinguquko zombala; Lawula impahla yomshini wokubuyisela. Kumafomula athambekele ekukhiqizeni "impahla yezimbali", zama ukungafihli ngokuqondile umshini wokubuyisela. Izinto zomshini wokubuyisela kufanele zixutshwe nezinto ezingavuthiwe futhi zichotshozwe kabusha; Sebenzisa i-ring dies yekhwalithi ephezulu ukuze ulawule ukushelela kwezimbobo zokufa, futhi uma kunesidingo, gaya izimbobo zokufa iringi ngaphambi kokusetshenziswa.

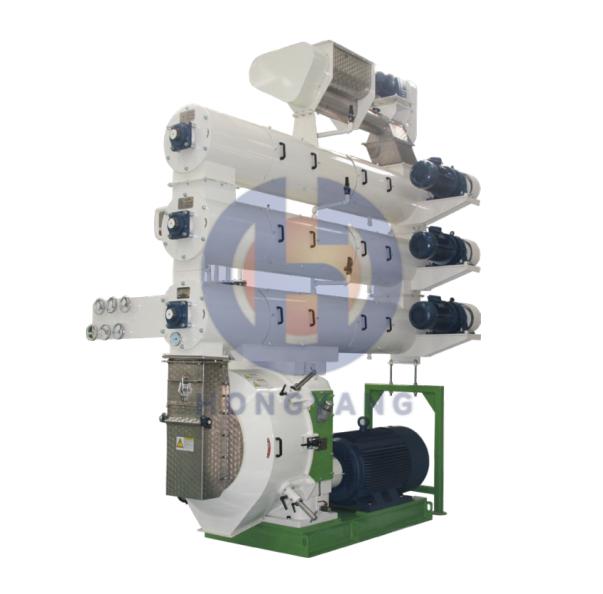

Kunconywa ukuthi ulungiselele i-conditioner ye-axis ekabili enezendlalelo ezimbili kanye ne-conditioner yejakhethi enezendlalelo ezimbili, enesikhathi sokucisha esingafika kumasekhondi angu-60-120 kanye nezinga lokushisa elicimayo elingaphezu kuka-100 ℃. I-quenching ifana futhi ukusebenza kuhle kakhulu. Ukusetshenziswa kwe-multi-point air intake kwandisa kakhulu indawo ye-cross-sectional yezinto ezibonakalayo kanye ne-steam, ngaleyo ndlela kuthuthukisa ukuvuthwa kwezinto ezibonakalayo nokuthuthukisa umphumela wokucisha nokushisa; Iphaneli yensimbi yedijithali nenzwa yezinga lokushisa ingabonisa izinga lokushisa lesimo, okwenza kube lula kubasebenzisi ukulawula noma kunini.

Ulwazi Lokuxhumana Lokusekela Lobuchwepheshe:

Whatsapp : +8618912316448

I-imeyili:hongyangringdie@outlook.com

Isikhathi sokuthumela: Jul-26-2023