Emkhiqizweni wangempela wokuphakelayo, ngenxa yezizathu ezihlukahlukene, “ibhodwe lempahla” lingakhiwa phakathi kweringi kanye nerola yokucindezela, okuholela ezinkingeni ezinjengokuminya, ukuvaleka, nokushelela kwegranulator.

Sifinyelele iziphetho ezilandelayo ngokuhlaziywa okusebenzayo nolwazi lwesayithi lecala:

Sifinyelele iziphetho ezilandelayo ngokuhlaziywa okusebenzayo nolwazi lwesayithi lecala:

1, Izinto ezibonakalayo ezingavuthiwe

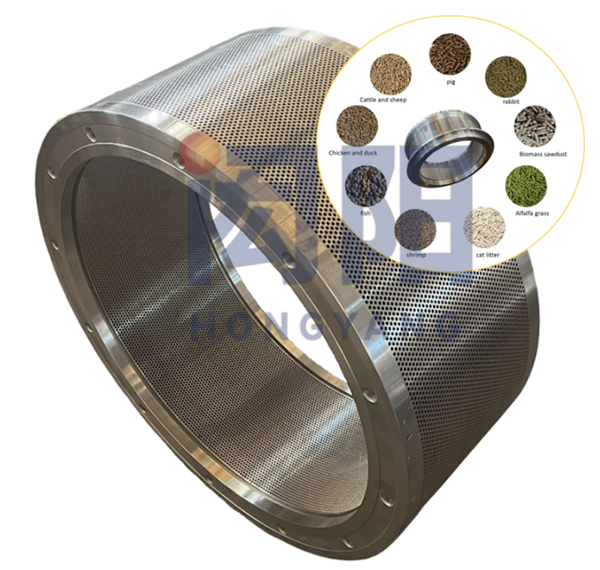

Izinto ezinokuqukethwe okuphezulu kwesitashi zijwayele ukugaya i-gelatinization futhi zibe ne-viscosity ethile, ehambisana nokubunjwa; Okwezinto ezisetshenziswayo ezinemicu ephezulu eqinile, inani lamafutha lidinga ukwengezwa ukuze kuncishiswe ukungqubuzana ngesikhathi senqubo ye-granulation, okuzuzisa ukuthi impahla idlule esikhunjeni sendandatho futhi okuwumphumela we-granular kube nokubukeka okubushelelezi.

2, Ukugunyazwa kwe-Die roll engafanele

Igebe phakathi kwama-mold rollers likhulu kakhulu, okwenza ungqimba lwempahla phakathi kwama-mold roller lube lukhulu kakhulu futhi lusatshalaliswe ngokungalingani. I-roller yokucindezela ijwayele ukushelela ngenxa yamandla angalingani, futhi impahla ayikwazi ukuminyanisa, okuholela ekuvinjweni komshini. Ukunciphisa ukuvinjelwa komshini, ukunakwa kufanele kukhokhwe ekulungiseni igebe phakathi kwama-rollers esikhunta ngesikhathi sokukhiqiza, ngokuvamile i-3-5mm ikhethwa.

3, Umthelela wekhwalithi yesitimu

3, Umthelela wekhwalithi yesitimu

Izimo ezifanele zenqubo ye-granulation yilezi: umswakama ofanelekile wempahla eluhlaza, ikhwalithi ye-steam enhle kakhulu, nesikhathi esanele sokufudumeza. Ukuqinisekisa ikhwalithi enhle yezinhlayiyana kanye nokuphuma okuphezulu, ngaphezu kokusebenza okuvamile kwezingxenye ezihlukahlukene zokudlulisela ze-granulator, ikhwalithi yesitimu esomile esigcwele esingena ku-conditioner ye-granulator kufanele futhi iqinisekiswe.

Izinga eliphansi le-steam liholela ekujuleni komswakama ophezulu wezinto ezibonakalayo lapho uphuma ku-conditioner, okungabangela kalula ukuvinjelwa kwembobo yesikhunta kanye nokushelela kwe-roller yokucindezela phakathi nenqubo ye-granulation, okuholela ekuvinjweni komshini. Iboniswa ngokuqondile ku-:

① Ukucindezela kwesitimu okunganele kanye nomswakama ophezulu kungabangela kalula okokusebenza ukuthi kumunce amanzi amaningi. Ngesikhathi esifanayo, lapho ingcindezi iphansi, izinga lokushisa lapho impahla ithambile nayo iphansi, futhi isitashi asikwazi ukugaya kahle, okuholela kumphumela omubi we-granulation;

② Ingcindezi yesitimu ayizinzile, iyaguquguquka isuka phezulu iye phansi, futhi ikhwalithi yezinto azinzile, okuholela ekuguquguqukeni okukhulu kwamandla we-granulator, ukoma okungalingani, kanye nokuvinjwa kalula phakathi nezinqubo zokukhiqiza ezijwayelekile.

Ukuze kuncishiswe inani lokuma kwemishini okubangelwa ikhwalithi yesitimu, abaqhubi befekthri yokuphakelayo badinga ukunaka okuqukethwe komswakamo kokubalulekile ngemva kokushisisa noma nini. Indlela elula yokunquma iwukuba ubambe idlanzana lezinto ku-conditioner bese uyibamba ebholeni, bese uyeke ukuthi uyihlakaze nje.

4. Ukusetshenziswa kweringi entsha kuyafa

4. Ukusetshenziswa kweringi entsha kuyafa

Ngokuvamile, lapho i-ring entsha iqala ukusetshenziswa, idinga ukugaywa ngezinto ezinamafutha, nokwanda okufanele okungaba ngu-30% wesihlabathi se-emery, futhi igaywe cishe imizuzu engama-20; Uma kukhona izinto eziningi egumbini le-granulation, futhi okwamanje kuncipha uma kuqhathaniswa nokugaya, kuzinzile, futhi ukuguquguquka kuncane. Ngalesi sikhathi, umshini ungamiswa futhi isimo se-granulation singabhekwa. I-granulation ifana futhi ifinyelela ngaphezu kwama-90%. Kuleli qophelo, sebenzisa izinto ezinamafutha ukuze ucindezele futhi ubuyisele izinto zesihlabathi ukuze uvimbele ukuvinjelwa okulandelayo.

5, Indlela yokuqeda ukuvinjelwa

5, Indlela yokuqeda ukuvinjelwa

Uma isikhunta sendandatho sivimbekile ngesikhathi sokukhiqiza, izimboni eziningi zokudla zisebenzisa izinsimbi zikagesi ukuze zibhoboze izinto, okuzolimaza ubushelelezi bembobo yesikhunta futhi kube yingozi kubuhle bezinhlayiya.

Indlela engcono etuswayo iwukuba ubilise isikhunta sendandatho ngamafutha, okuwukusebenzisa ipani lamafutha ensimbi, ufake amafutha enjini engcolile, ucwilise isikhunta esivinjiwe kuso, bese usishisa futhi usisitile ngezansi kuze kube yilapho kuzwakala umsindo oqhephukayo, bese uyasikhipha. Ngemuva kokupholisa, ukufakwa kuqediwe, futhi i-granulator iqalwa kabusha ngokuya ngemininingwane yokusebenza. Izinto ezivimba isikhunta sendandatho zingahlanzwa ngokushesha ngaphandle kokulimaza ukuphela kwezinhlayiyana.

Isikhathi sokuthumela: Jul-19-2023