Uma uqaphela ngokuzumayo ukwanda okungazelelwe komsindo ovela emshinini wokugaya i-pellet ngesikhathi senqubo yokukhiqiza, udinga ukunaka ngokushesha, njengoba lokhu kungase kubangelwe izindlela zokusebenza noma izizathu zangaphakathi zemishini.Kuyadingeka ukuqeda ngokushesha izinkinga ezingaba khona ukuze ugweme ukuthikameza ukukhiqizwa okuvamile okulandelayo.

Kunezici eziningana ezibangela umsindo ophezulu we-pellet mill, ongaqhathaniswa futhi uqondiswe.

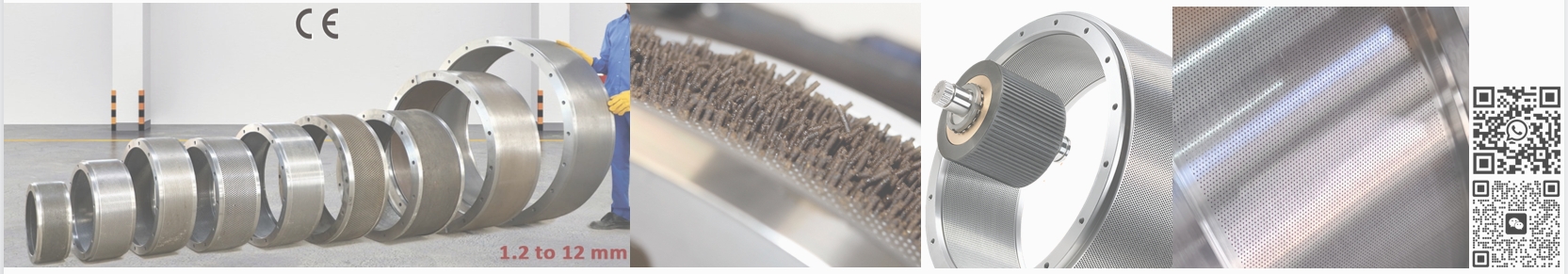

1. Ukuvinjwa kwesikhunta esiyindandatho, ngenxa yokuyindilinga, ukukhishwa okuyingxenye kuphela;Igebe phakathi kwesikhunta sendandatho ye-pressure roller lincane kakhulu noma silimele, elivimbela ukuthi lijikeleze.(Hlola noma shintsha isikhunta sendandatho, lungisa igebe phakathi kwamarola okucindezela).

2. I-bearing inenkinga futhi okokusebenza akusebenzi kahle, okuholela ekusebenzeni okuphezulu kwamandla.(Ishintsha ama-bearings)

3. Ukuhlanganisa akulingani futhi kukhona ukuphambuka ekuphakameni kwesobunxele nakwesokudla, okwenza kube lula ukulimaza uphawu lwamafutha we-gear shaft.(Ukuhlanganisa ukulungiswa kwebhalansi)

4. Ukukhishwa okungalingani kwembobo yokukhipha i-modulator kuholela ekushintshashintsheni kwamanje okukhulayo kumshini wokugaya.(Lungisa ama-modulator blades futhi ukhiphe ngokulinganayo okokusebenza)

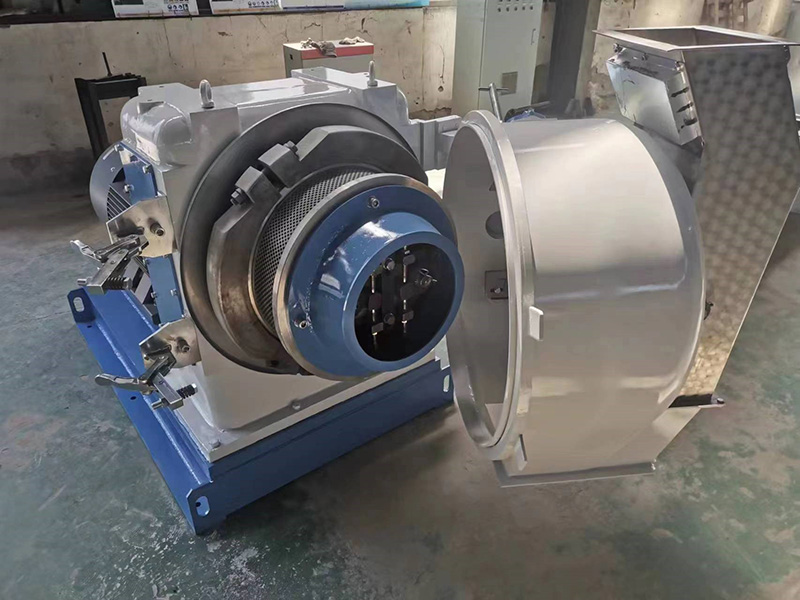

5. I-spindle ixega, okwenza inqubo yokukhiqiza iye emuva naphambili, okuholela ekunyakazeni okuphawulekayo kwerola yokucindezela kanye nomsindo obalulekile phakathi ne-granulation.(Qinisa umphimbo)

6. Ngaphambi kokusebenzisa i-roller entsha yokubumba iringi, idinga ukugaywa futhi ipholishwe ngaphambi kokusetshenziswa.(Susa ukubunjwa kwendandatho yekhwalithi ephansi)

7. Ukugqokwa kwamagiya amakhulu namancane, noma ukushintshwa kwamagiya, nakho kungadala umsindo owengeziwe.(Kudingeka ugijime isikhathi esithile)

8. Lawula ngokwesayensi isikhathi sokushisa nezinga lokushisa.Izinto ezome kakhulu noma ezimanzi kakhulu zingabangela i-granulation engavamile.

9. I-chassis kanye nesakhiwo sefreyimu yensimbi ye-pellet mill ayiqinile futhi ijwayele ukudlidliza.(Qinisekisa isakhiwo bese ukhetha imishini ye-granulation yekhwalithi ephezulu)

10. Umsila we-modulator awugxili ngokuvikelekile noma awukhululekile.(Bheka ukuqiniswa)

Isikhathi sokuthumela: Dec-04-2023