Izizathu zokuqhekeka kwesikhunta esiyindandatho ziyinkimbinkimbi futhi kufanele zihlaziywe ngokuningiliziwe;nokho, zingafingqwa ngezizathu ezilandelayo:

1. Ibangelwa ring die material kanye nekhwalithi engenalutho

1)Impahla esetshenziswe kwi-ring die ingesinye sezizathu ezibalulekile.Njengamanje, iringi yaseChina iyafa ikakhulukazi isebenzisa i-4Cr13 ne-20CrMnTid, ezinzile uma kuqhathaniswa.Nokho, kukhona abakhiqizi abahlukene bezinto zokwakha.Ngempahla efanayo, kuzoba khona umehluko othile ezintweni zokulandelela, ezizothinta ikhwalithi yesikhunta sendandatho.

2)inqubo yokuqamba.Lesi isixhumanisi esibalulekile enqubweni yokukhiqiza isikhunta.Ezikhunjini zensimbi ze-alloy ephezulu, ngokuvamile kunezidingo zesakhiwo se-metallographic njengokusabalalisa kwe-carbide kumpahla.Izinga lokushisa lokukhohlisa kufanele futhi lilawulwe ngokuqinile, imininingwane yokushisisa efanele kufanele yenziwe, izindlela zokufoja ezifanele kufanele zamukelwe, futhi ukupholisa kancane noma ukucwiliswa okufika ngesikhathi ngemva kokufoja kufanele kwenziwe.Izinqubo ezingavamile zingaholela kalula ekuqhekekeni kwe-ring die body.

3)Ukulungiselela ukwelashwa ukushisa.Ngokuya ngezinto kanye nezidingo zesikhunta, izinqubo zokulungiselela zokwelashwa kokushisa okufana ne-annealing and quenching and tempering zisetshenziselwa ukuthuthukisa isakhiwo, ukuqeda ukukhubazeka kwesakhiwo ekubunjweni nasekuvuleni, kanye nokwenza ngcono ukucutshungulwa.Ukwelashwa okufanele okulungiselela ukushisa kwensimbi ephezulu ye-carbon alloy mold kungaqeda ama-carbide enethiwekhi, i-spheroidize futhi icwengisise ama-carbides, futhi ikhuthaze ukusatshalaliswa kwe-carbide efanayo.Lokhu kuzosiza ukuqinisekisa ikhwalithi yokucisha nokushisa futhi kwandise impilo yesikhunta.

2. Ukwelashwa kokushisa kweringi

1)ukuphefumula nokuphefumula.Lesi isixhumanisi esiyinhloko ekwelapheni ukushisa kwesikhunta.Uma ukushisa ngokweqile kwenzeka ngesikhathi sokucisha nokushisa, ngeke nje kubangele ukuqina okukhulu kwe-workpiece, kodwa futhi kubangele kalula ukuguqulwa nokuqhekeka ngesikhathi sokupholisa, okuthinta kakhulu impilo yesikhunta.Ukucaciswa kwenqubo yokwelapha ukushisa kufanele kulawulwe ngokuqinile futhi ukwelashwa kokushisa kwe-vacuum kufanele kusetshenziswe.Ukushisa kufanele kwenziwe ngesikhathi ngemuva kokucisha, futhi izinqubo ezahlukene zokushisa kufanele zamukelwe ngokuvumelana nezidingo zobuchwepheshe..

2)i-stress annealing.Isikhunta kufanele sibe ngaphansi kokunciphisa ingcindezi ngemva komshini onzima ukuze kuqedwe ingcindezi yangaphakathi ebangelwa umshini onzima ukuze kugwenywe ukuwohloka okukhulu noma imifantu ebangelwa ukucisha.Ezikhunjini ezinezidingo zokunemba okuphezulu, ukwelashwa kokunciphisa ukucindezeleka kuyadingeka ngemva kokugaya, okuzuzisa ukuzinzisa ukunemba kwesikhunta nokwandisa impilo yayo yesevisi.

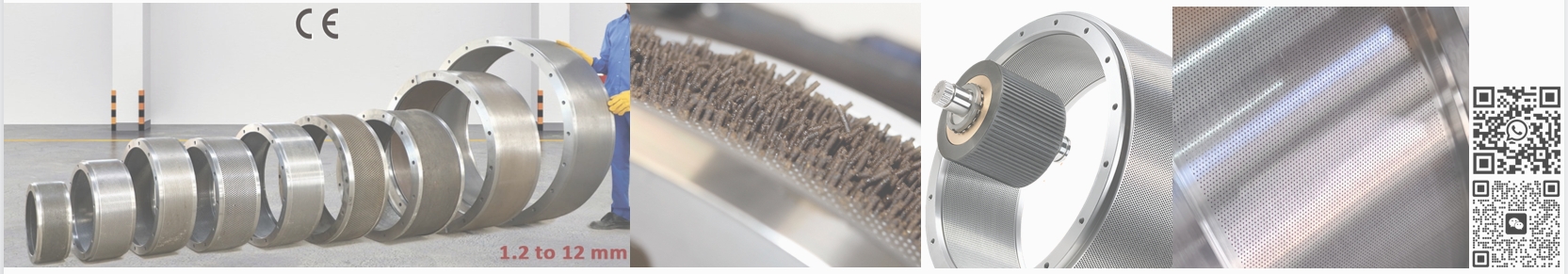

3. Ukuvula isilinganiso sesikhunta sendandatho

1)Uma izinga lokuvula leringi liphezulu kakhulu, amathuba okuqhekeka kweringi azokhuphuka.Umkhiqizi ngamunye wesikhunta esiyindandatho uzoba nomehluko omkhulu ngokuqhathaniswa ngenxa yamazinga ahlukene wokwelapha ukushisa nezinqubo.Ngokuvamile, imikhiqizo yenkampani yethu ingakhuphula izinga lokuvula ngo-2-6% ngesisekelo sesikhunta sasekhaya sesigaba sokuqala, futhi ingaqinisekisa impilo yesevisi yesikhunta esiyindandatho.

4. Ukugqoka indandatho

1)Lapho indandatho yokufa igqokwa ekugqimeni okuthile futhi amandla ancishiswa kuze kube yilapho engakwazi ukumelana nokucindezela kwe-granulation, ukuqhekeka kuzokwenzeka.Kutuswa ukuthi idayizi yeringi ishintshwe ngesikhathi lapho indandatho igqokwa khona kuze kube seqophelweni lapho ama-groove e-pressure roller eshaywa khona.

5. Ukusetshenziswa kwe-ring die

1)Ngesikhathi senqubo ye-granulation yeringi, inani lempahla engenayo alikwazi ukuvunyelwa ukuthi lisebenze ngomthwalo ongu-100% ngenxa yokukhishwa okuphezulu kwe-granulation yeringi ngokwayo.Ukusebenza okunjalo kwesikhathi eside nokuqina kuzoholela ekuqhekekeni kweringi..Sincoma ukuthi ulawule umthwalo ku-75-85% ukuze uqinisekise impilo yesevisi yeringi.

2)Uma i-ring die kanye ne-pressure roller icindezelwe kakhulu, ukuqhekeka kungenzeka kalula.Ngokuvamile, sidinga ukuthi ibanga eliphakathi kokufa kweringi kanye nerola yokucindezela kufanele lilawulwe phakathi kuka-0.1-0.4mm.

6. Ama-Sundries

1) Ukuqhekeka kungenzeka kakhulu lapho izinto eziqinile ezifana namabhulokhi ensimbi zivela ezintweni ze-granulated.

7. Ukufakwa kwe-ring die kanye nezinkinga ze-granulator

1) I-ring die ayifakiwe ngokuqinile futhi kukhona igebe phakathi kwayo ne-granulator.Iringi nayo ingase iqhekeke ngesikhathi senqubo ye-granulation.

2) Ngemuva kokwelashwa kokushisa, isikhunta sendandatho sizokhubazeka kakhulu.Uma ingalungiswa, isikhunta sendandatho sizoqhekeka ngesikhathi sokusetshenziswa.

3) Uma i-granulator ngokwayo inesici, njenge-shaft eyinhloko ye-granulator enyakazayo, njll.

Ulwazi Lokuxhumana Lokusekela Lobuchwepheshe:

Whatsapp: +8618912316448

E-mail:hongyangringdie@outlook.com

Isikhathi sokuthumela: Jan-25-2024