Ekucutshungulweni kwesiphakeli se-pellet, izinga eliphezulu lokuphulukisa alithinti nje kuphela izinga lokuphakelayo, kodwa futhi linyusa izindleko zokucubungula.Ngokuhlola amasampula, izinga lokuhlikihla lokuphakelayo lingabonwa ngokubonakalayo, kodwa akwenzeki ukuqonda izizathu zokuhlikihla kunqubo ngayinye.Ngakho-ke, kunconywa ukuthi abakhiqizi bokudla baqinise ukuqapha okuphumelelayo kwesigaba ngasinye futhi basebenzise izinyathelo zokuvimbela nokulawula ngesikhathi esisodwa.

1. Ifomula yokuphakelayo

Ngenxa yomehluko ekwenziweni kokuphakelayo, ubunzima bokucubungula bungahluka.Isibonelo, ukudla okunamaprotheni angcolile aphansi kanye nokuqukethwe kwamafutha kulula ukugaywa futhi kucutshungulwe, kuyilapho okuphakelayo okunokuqukethwe okuphezulu mancane amathuba okuba kwakheke, okuholela ezinhlayiyeni ezixegayo kanye nezinga eliphezulu lokuputshuza.Ngakho-ke lapho ucubungula i-feed granulation ngokugcwele, ifomula iyimfuneko, futhi ubunzima bokucubungula kufanele bucatshangelwe ngangokunokwenzeka ukuze kuqinisekiswe ikhwalithi iyonke.Njengekhasimende le-Hongyang Feed Machinery, singakunikeza amafomula okuphakelayo ochwepheshe ukuze ukwandise ikhwalithi yakho. umthamo wokukhiqiza kanye nokwenza ngcono izinga lokudla.

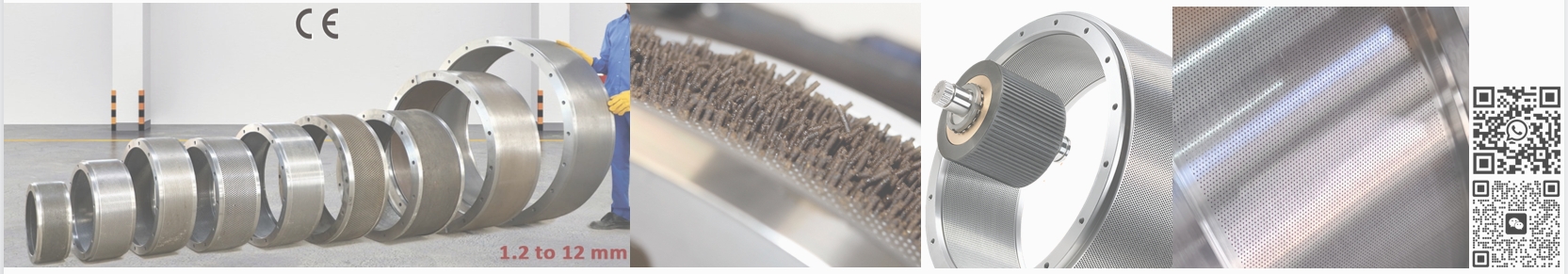

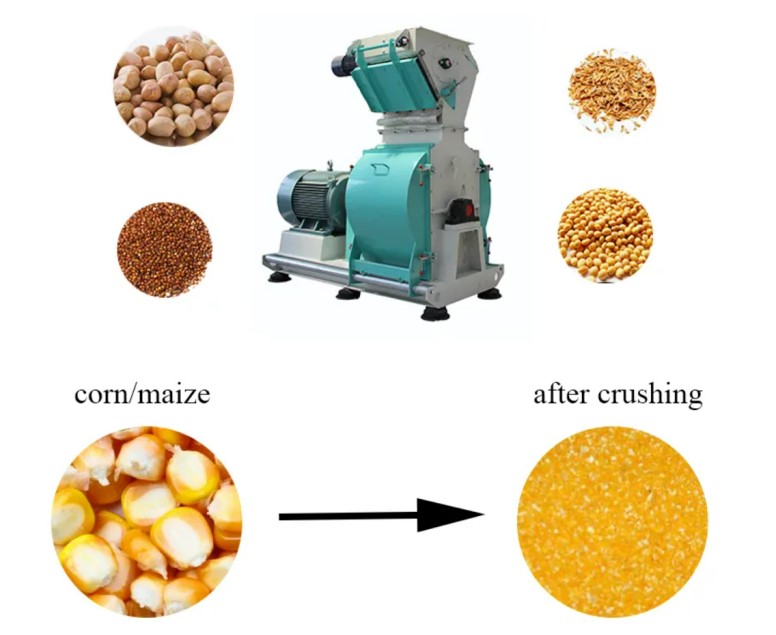

2, Isigaba sokuchoboza

Ubukhulu bezinhlayiyana zokuchotshozwa kwezinto ezingavuthiwe buncane, indawo engaphezulu yempahla iba nkulu, iba ngcono ukunamathela ngesikhathi segranulation, futhi ikhwalithi yegranulation iyanda.Kodwa uma incane kakhulu, izobhubhisa ngokuqondile izakhi.Ukukhetha osayizi abahlukene bezinhlayiya ezichotshozwayo ngokusekelwe ezidingweni zekhwalithi eziphelele nokulawulwa kwezindleko kubalulekile.Ukusikisela: Ngaphambi kokugaya imfuyo kanye nokudla kwezinkukhu, ubukhulu bezinhlayiyana zempushana kufanele okungenani bube yizinetha eziyi-16, futhi ngaphambi kokugcwalisa ukudla kwasemanzini, usayizi wezinhlayiyana zempushana kufanele okungenani ube ngamanetha angama-40.

3. Ingxenye yegranulation

Okuqukethwe kwamanzi aphansi noma aphezulu, izinga lokushisa eliphansi noma eliphezulu elishisayo konke kunomthelela omkhulu kukhwalithi ye-granulation, ikakhulukazi uma iphansi kakhulu, izokwenza i-granulation yezinhlayiya zokuphakelayo ingaqini, futhi izinga lokulimala kwezinhlayiyana nezinga lokuphulukisa lizokhuphuka.Ukusikisela: Lawula okuqukethwe kwamanzi ngesikhathi sokushisa phakathi kuka-15-17%.Izinga lokushisa: 70-90 ℃ (isitimu se-inlet kufanele sicindezeleke sibe ngu-220-500kpa, futhi izinga lokushisa lomusi ongenisayo kufanele lilawulwe cishe ku-115-125 ℃).

4. Isigaba sokupholisa

Ukupholisa okungalingani kwezinto noma isikhathi sokupholisa ngokweqile kungabangela ukuqhuma kwezinhlayiyana, kubangele izindawo zokuphakelayo ezingajwayelekile neziphuka kalula, ngaleyo ndlela kukhuphule izinga lokuputshuza.Ngakho-ke kuyadingeka ukukhetha imishini yokupholisa enokwethenjelwa futhi upholise ngokulinganayo izinhlayiya.

5. Isigaba sokuhlola

Ugqinsi oludlulele noma ukusatshalaliswa okungalingani kongqimba lwezinto zesikrini sokugreda kungaholela ekuhlolweni okungaphelele, okuholela ekwenyukeni kokuqukethwe okuyimpushana kumkhiqizo oqediwe.Ukuphuma ngokushesha kwesipholile kungabangela kalula ukushuba okweqile kongqimba lwesisefo sokugreda, futhi kufanele kuqashelwe ukukunqanda.

6, Isigaba sokupakisha

Inqubo yokupakishwa komkhiqizo oqediwe kufanele wenziwe ngenqubo yokukhiqiza eqhubekayo, indawo yokugcina impahla eqediwe igcina okungenani i-1/3 yomkhiqizo oqediwe ngaphambi kokuqala ukupakisha, ukuze kugwenywe ukwanda kwempushana emkhiqizo oqediwe obangelwa ukuphakelwa. ewa endaweni ephakemeyo.

Isikhathi sokuthumela: Oct-24-2023