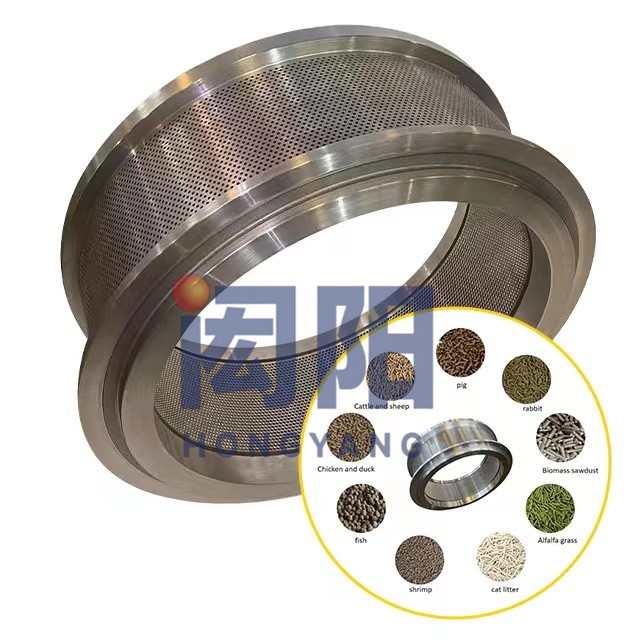

I-ring die iyingxenye ebalulekile ye-feed granulator/pellet mill, futhi ukusebenza kwayo ikakhulukazi kunquma ukuphuma kokucubungula okuphakelayo, okudlala indima ebaluleke kakhulu enqubweni yokucubungula okuphakelayo. Kodwa-ke, amanye amakhasimende abike ukuthi ngesikhathi sokukhiqiza, indandatho ingase iqhume.

Izizathu ezilandelayo zafingqwa ngokuhlolwa:

1. Ukusebenza kwempahla esetshenziswe kukufa kweringi akuzinzile futhi akulingani;

2. Uma izinga lokuvula leringi liphezulu kakhulu, amandla nokuqina kweringi kuzokwehla;

3. Ugqinsi lwefasi yeringi mncane kakhulu, futhi amandla okufa kweringi ayancipha;

4. Iringi iphonswa ngenkani izinto eziqinile ngesikhathi sokusebenza;

5. Isimo se-eccentric noma ukuqina kokungalingani kwendandatho kuyafa ngesikhathi sokufakwa (okugxile ekuhlanganiseni kwerola yokucindezela, njll.) kubangela ukuba indandatho ishone ukuthi imelane ngokuqhubekayo nomthelela we-unidirectional.

Isikhunta esishubile/indandatho iyafa ukuze kuthuthukiswe ikhwalithi yezinhlayiya, ngenxa yokwanda kwama-pellets okuphakelayo kanye nokungqubuzana phakathi kodonga olufayo, nakho kukhuphule izinga le-starch gelatinization. Kodwa-ke, ukusebenzisa isikhunta esijiyile noma sokuvula indawo encane kunganciphisa ukukhiqiza. Ngaphezu kwalokho, ibanga phakathi kwama-roller kanye nesikhunta lenyuke lisuka ku-0.1 mm laya ku-2 mm, lingathuthukisa ukuqina kwezinhlayiya.

Njengekhasimende le-Hongyang Feed Machinery Company yethu, sihlinzeka amakhasimende ngendandatho ephezulu efayo, ehlala isikhathi eside, futhi inamandla okukhiqiza aphezulu. Sincoma futhi senze ngendlela oyifisayo isilinganiso sokuminyanisa esifaneleka kakhulu nesimbobo samakhasimende.

Ulwazi Lokuxhumana Lokusekela Lobuchwepheshe:

TEL/Whatsapp : +86 18912316448

E-mail:hongyangringdie@outlook.com

Isikhathi sokuthumela: Sep-11-2023